The next step in PVCu welding evolution

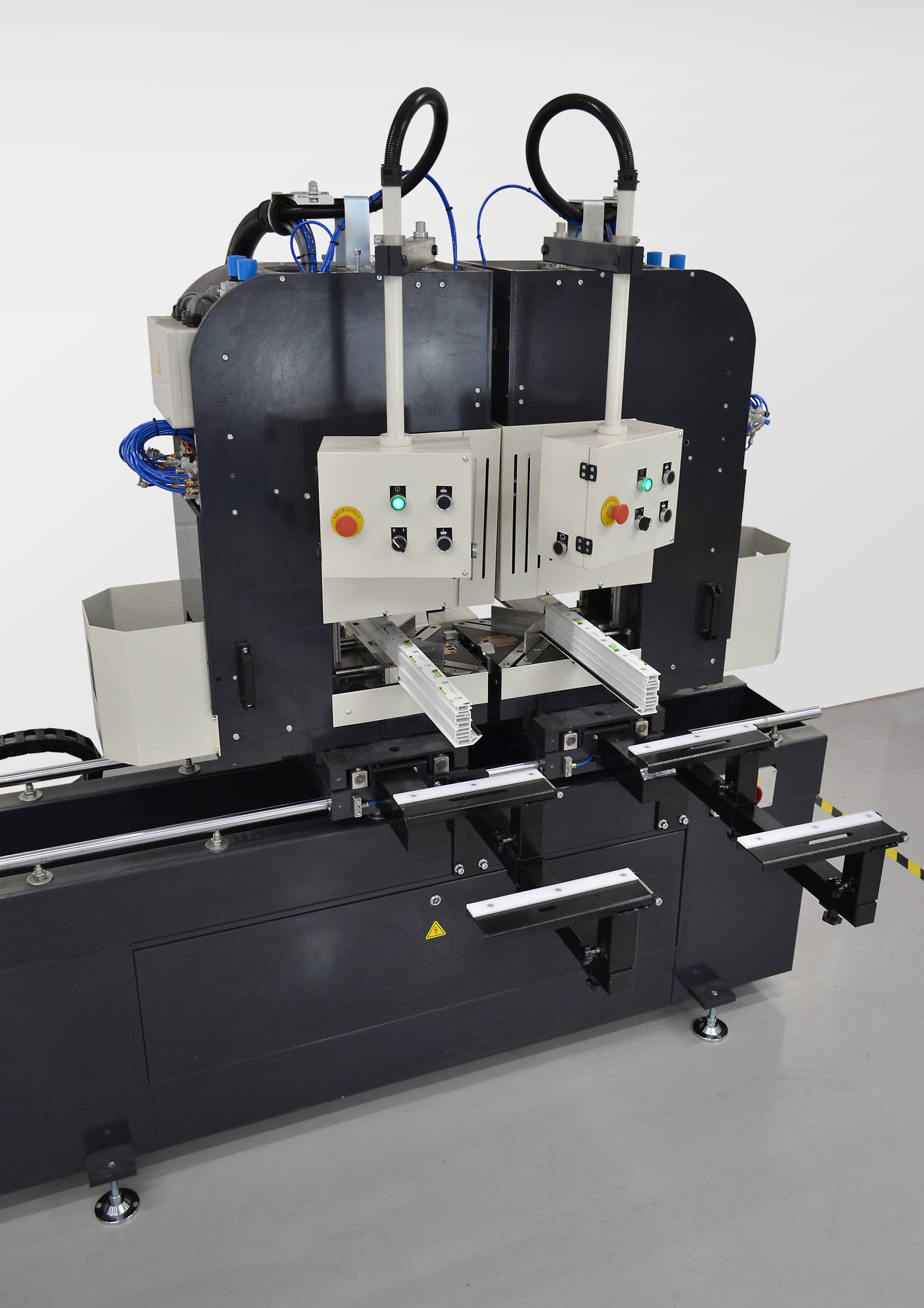

Avantek Machinery is excited to introduce the latest development in its inline PVCu window and door manufacturing range. The Wegoma 6-head Inline Hybrid Welder has been engineered to maximise production capacity and efficiency while maintaining the highest quality standards.

Automatic vs universal welders

Understanding the primary differences between fully automatic and universal welders is crucial in deciding which inline welding machine will best suit your manufacturing needs.

Avantek Sales Director, Jamie Munday explains, “Auto welders are equipped with features which include: colour PLC with touch screen control of all welding functions, a quick release profile support block system, pneumatic transom self-centring systems, and a servo motor-controlled head alignment system, plus much more.

“All of this greatly increases the speed and accuracy of the welder compared to a standard inline universal (or uni) welder.”

The best of both worlds

Discussing the design of Avantek’s 6-head Inline Hybrid Welder, Jamie Munday states, “This unique six-head inline configuration features four fully automatic heads, plus two additional universal heads which have been specially adapted to produce H-welds as narrow as 370mm when turreted.”

He continues, “The cutting-edge addition to Avantek’s range reaches new heights in versatility allowing many welding combinations in one, cost-effective machine.

“This brand-new model allows the operation of four fully automatic heads, while simultaneously using the two additional universal heads in a turreted position independently – essentially providing the functionality of two machines in one.

“It’s a groundbreaking design that maximises efficiency by reducing the total number of welding cycles without compromising working with steel reinforcements. Furthermore, it can be used as an inline 6-head welder when not using the turreting capacity of the two universal heads.”

User-driven design process

The Avantek Machinery team understand that drawing on customer feedback during new product development allows needs and preferences to be identified, ideas to be validated, and helps refine new features.

Jamie explains, “In our pursuit of design innovation, we work closely with our customers to fully understand their requirements and get a clear idea of the user experience.

“This allows us to communicate insights to our suppliers and engineer manufacturing solutions from the ground up. It’s a collaborative approach that ensures we continuously redefine the benchmarks of machinery performance.

“By incorporating user input, we’ve designed and built a welder unlike anything else currently available on the market. We’ve also listened to what Avantek fabricator-customers are saying about market trends, carefully designing the two, turreting universal heads so that they can produce narrower sashes and smaller openings, catering to strong consumer demand for these types of windows and doors.”

A comprehensive 6-Head inline range

Jamie concludes, “At Avantek we’re proud to offer our customers a wide range of machinery solutions that meet a diverse range of manufacturing requirements. Our Wegoma 6-head inline welder range is now available in 6-head auto, 6-head uni and 6-head hybrid configurations. This means we have a comprehensive armoury for our customers to choose from.

For more information and to arrange a face-to-face demonstration contact sales@avantekmachinery.co.uk